Infrared heating

Infrared heating – the term characterising heating by radiation (emission, radiation) in the form of electromagnetic waves in the infrared spectrum (wavelength 0.7-10 µm). Electromagnetic waves radiated by a hot object are spread through the space and are absorbed by a cold object where they “vibrate” its atoms and increase its temperature.

The radiation is also spread via vacuum, which is used for heating objects in a vacuum. (The vacuum cannot be heated.) The infrared heating is used for heating solid particles and liquids “remotely”. The infrared heating of gases is not effective. The higher the temperature of the infra emitter, the greater volume of radiated energy.

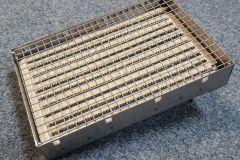

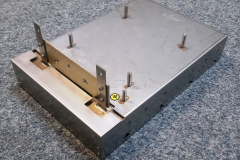

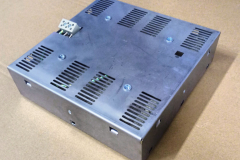

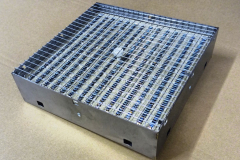

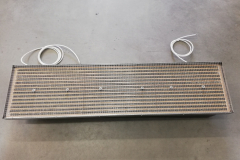

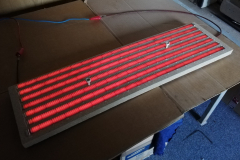

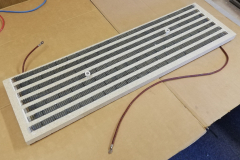

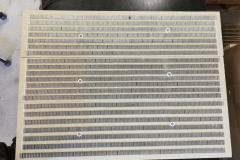

Heating elements for infrared heating are produced from high-loaded cartridges, tubular heating elements or open wire heaters are applied.

To increase the ratio of infrared radiation, the surface of the element is treated in some cases (e.g. black oxidation or silicating) due to the increase in emissivity and efficiency.

Information necessary for processing tasks for heating items by radiation

- Time required for heating.

- Specification of material, including specification of the surface to determine emissivity.

- Starting and target temperature.

- Size, shape, and weight of the location and the distance from the heater.

- Other sources of heat, if they exist.

Advantages and disadvantages

Advantages of infrared heating:

- Contact-free heating – can be used on moving manufacturing lines.

- Speed of heating – in practice, it is 3x faster than heating by flowing.

- High efficiency – the surrounding air is not heated; the effect is concentrated on the heated object.

Disadvantages of infrared heating

- It cannot be applied to objects with inappropriate emissivity, which is mainly attributed to glossy objects. On the contrary, they reflect infrared waves and can be used to direct infra waves in the desired direction.