Mica plate heaters

We produce flat heating mica elements according to the requirements of the client.

Termination options

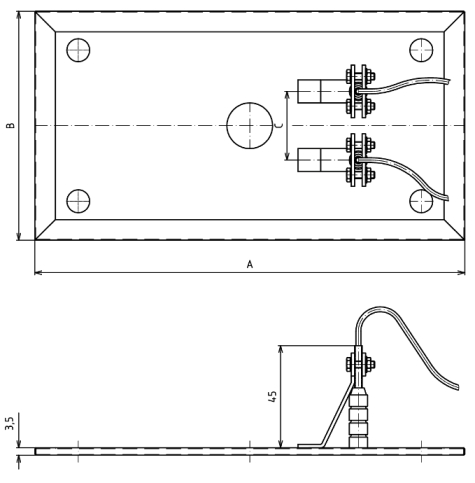

1) Leads perpendicular to the area of the element

- Leads with silicon insulation and copper galvanized core (maximally up to 180°C).

- Leads with Teflon insulation and copper galvanized core (maximally up to 205°C).

- Leads with Teflon insulation and nickel core (maximally up to 260°C).

- Leads with glass-textile insulation and nickel core (maximally up to 350°C).

- Leads with mineral insulation and nickel galvanized core (maximally up to 450°C).

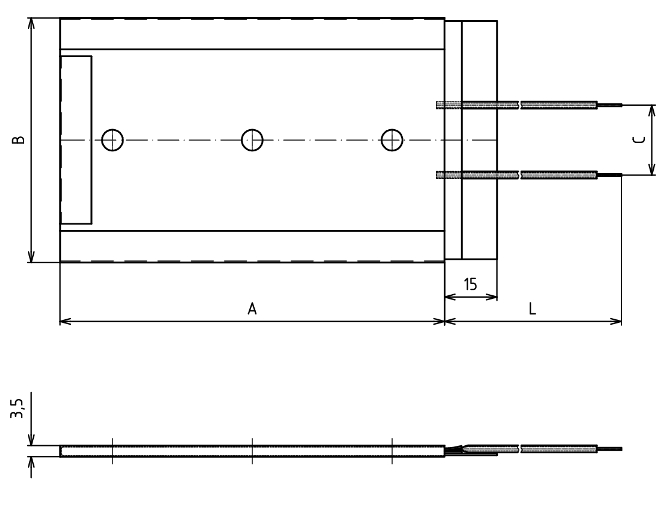

2) Leads in the plane of the element

- Nickel wire with glass-textile hose (maximally up to 250°C).

- Leads with Teflon insulation and nickel core (maximally up to 260°C).

- Leads with glass-textile insulation and nickel core (maximally up to 350°C).

- Conductors with mineral insulation and nickel galvanized core (maximally up to 450°C).

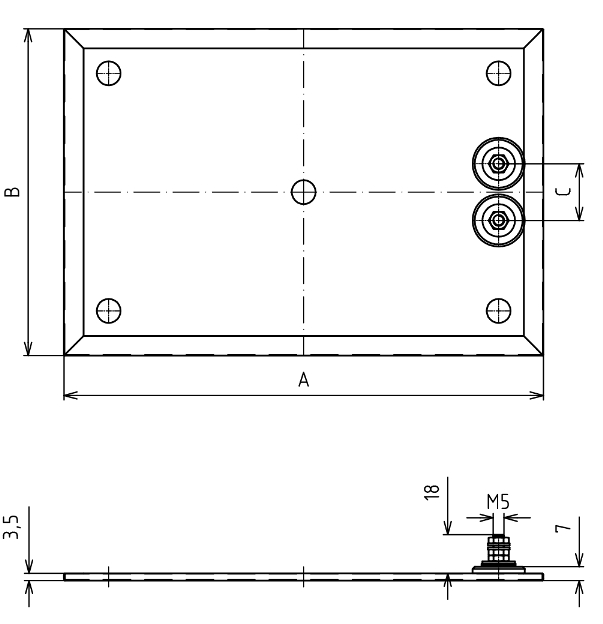

3) clams M5:

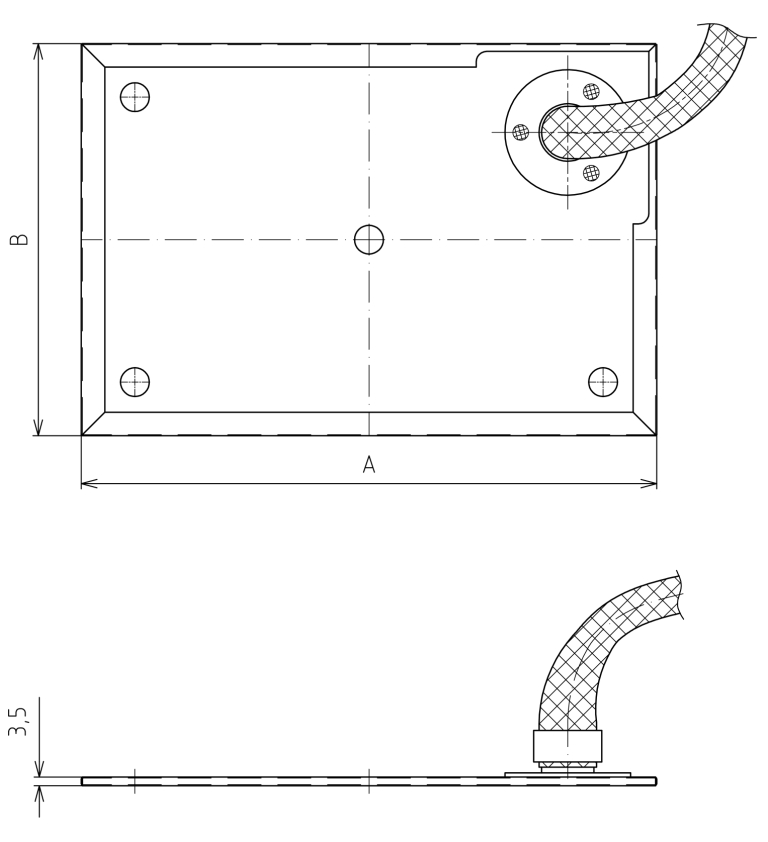

4) Leads fitted with metal braid:

- Leads with glass-textile insulation and nickel core (maximally up to 350°C).

- Leads with mineral insulation and nickel galvanized core (maximally up to 450°C).

Specification

Standard thickness of the element: 4 mm +/-0.5

Wattage tolerance: +10%/-10% (measured at working temperature).

Operating voltage: 12 V – 400 V

Material for the shell: AISI 304, brass, steel.

Maximum recommended working temperature on the surface of the belt: 350°C.

Maximum recommended watt density of mica plate heaters: 3-4 W/cm2 (depends on the dimensions of the element, the working temperature, and the material of the heated part).

Maximum recommended working temperature: 300°C (according to the dimensions of the element, the specific load, the method of suppression, and the heated material).

Option to mount “K” and “J” type thermocouples.