Flat tubular heaters

Flat tubular flat heating elements (flat heating rods) are recommended for use in a wide range of applications due to their shaping. For the option of single and double ended termination of rods or locating a thermocouple inside the rod, see the choice of connections for individual rod profiles.

Produced profiles: 12×6.5mm; 12×6.3mm; 21×6.5mm; 17.2×5.5mm; 16×6.5mm; 13.5x5mm; 11.5×4.5; 10.5×3.8mm; 7.2×2.7mm; 4.2×2.2mm.

Specification of flat heating rods

| Rod profile [mm] | 7.2×2.7 | 10.5×3.8 | 11×4.1 | 11.5×4.5 | 12×6.5 (12.5×6.3) |

13.5×5 | 16×6.5 | 17.2×5.5 | 21×6.5 |

| Maximum voltage | 240V | 240V | 400V | 400V | 400V | 400V | 400V | 400V | 400V |

| Maximum Amperage per spiral | 10A | 12A | 16A | 16A | 16A | 12A | 16A | 16A | 16A |

| Maximum length [m] | 3 m | 3 m | 6 m | 6 m | 10 m | 10 m | 10 m | 10 m | 6 m |

| Tolerance of the length of the rod [mm] | +0 -2 |

+0 -2 |

+0 -2 |

+0 -2 |

+0 -2 |

+0 -2 |

+0 -2 |

+0 -2 |

+0 -2 |

| Tolerance of the width of the profile [mm] | +0 -0.2 |

+0.3 -0.3 |

+0.1 -0.5 |

+0 -0.6 |

+0 -0.3 |

+1 -0.5 |

+0.4 -0.3 |

+0.3 -0.3 |

+0.3 -0.2 |

| Tolerance of the profile thickness [mm] | +0.15 -0.15 |

+0.2 -0.1 |

+0.15 -0.15 |

+0.2 -0.2 |

+0 -0.3 |

+0.5 -0.3 |

+0.15 -0.4 |

+0.2 -0.1 |

+0.1 -0.3 |

The value of the maximum recommended Amperage does not apply to all types of leads.

Wattage power tolerance:

- +5%/-10% above 200 W of the nominal Wattage (measured at working temperature).

- +10%/-10% up to 25 W – 200 W of the nominal Wattage (measured at working temperature).

The sheath material and the recommended watt density of the heating rods (W/cm2) is stated according to the working conditions for the element (see Heating gases, liquids, and solid substances).

Materials used for the sheath: AISI 304, AISI 321, AISI 316L, AISI 316Ti, INCOLOY 800, steel 11 353, copper, aluminium (all materials are immediately available or from a technological viewpoint, only applicable to profiles 12.5 mm x 6.3 mm and 12 mm x 6.5 mm).

For the application for heating gases, there is the option of winding profiles 12.5×6.3, 12×6.5 with a stainless strip to increase the area of the heat passage into the space and to increase the service life of the rod or the maximum recommended value of the watt density of the rod for specific working conditions (see Heating gases).

For more information, or in the case of other parameters than those mentioned above, please contact us.

Standard methods of sealing tubular heating elements

Polyurethane sealant (up to 135 °C) – is used for elements with low working temperature, e.g. heating water.

Epoxy resin (up to 146 °C) – reports higher mechanical resistance compared with polyurethane sealants.High chemical resistance to acids and alkalis.

Silicone sealant (guaranteed up to 275 °C) – elements for air. Not suitable for applications requiring increased resistance to humidity.

High temperature epoxy resin – air and liquids up to 250 °C. High chemical resistance to acids and alkalis.

Ceramic sealant (up to 1,500 °C) – application with high working temperatures. Not suitable for applications requiring increased resistance to humidity.

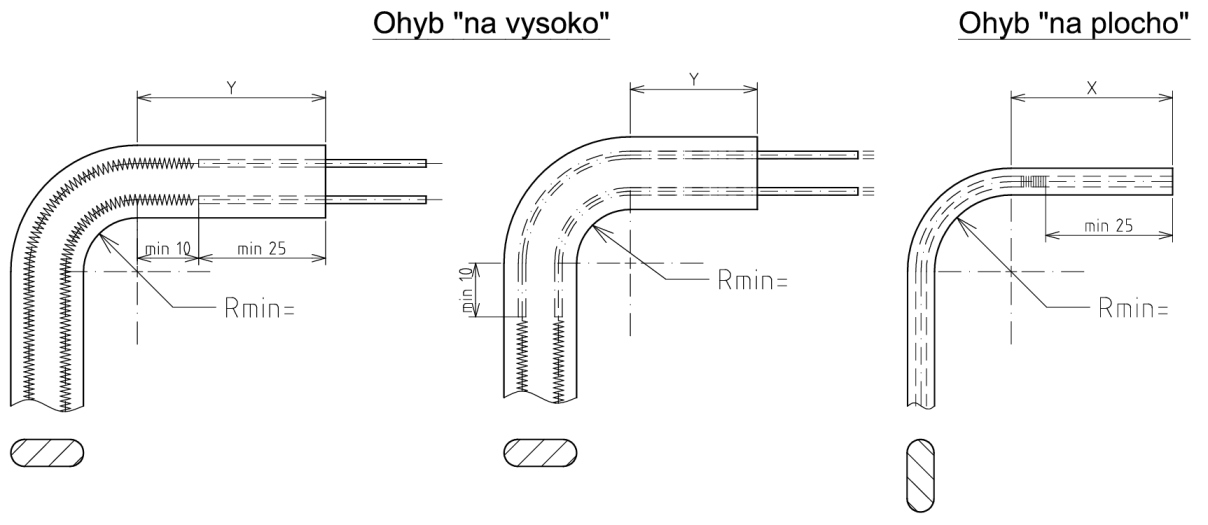

Construction limits

| Rod profile (mm) | 7.2×2.7 | 10.5×3.8 (11×4.1) |

11.5×4.5 | 12×6.5 (12.5×6.3) |

13.5×5 | 16×6.2 (17.2×5.5) |

21×6.5 |

| Min. radius of bending “on flat” Rpmin (mm) | 10 | 10 | 10 | 10 | 10 | 13 | 18 |

| Min. radius of bending “to the high” Rpmin (mm) | 15 | 15 | 15 | 15 | 20 | 20 | 75 |

| X (mm) | 13 | 20 | 25 | 10 | 10 | 10 | 50 |

| Y (mm) | 25 | 25 | 30 | 30 | 30 | 40 | 60 |

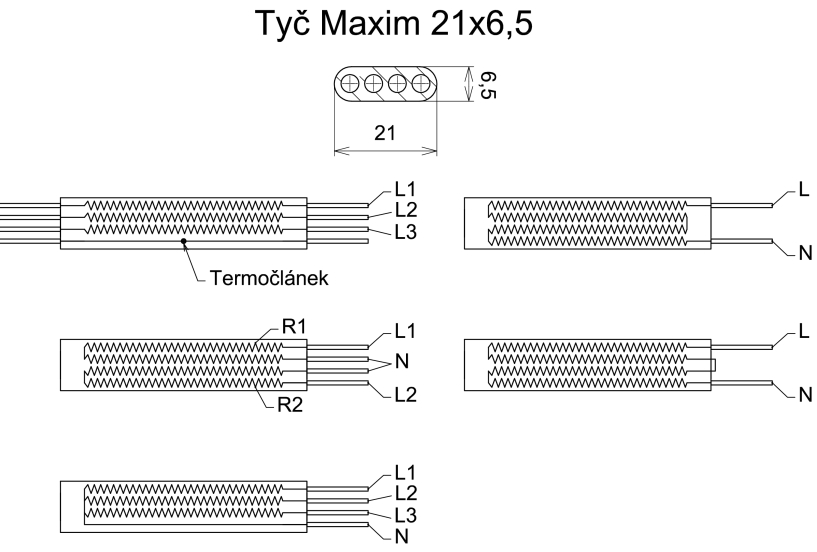

Connection options

Terminations – flat tubular elements

1) Nickel (brass) leads. Applicable for all profiles for flat heating rods.

2) Leads with insulation are connected outside the heating rod. Applicable for all profiles for flat heating rods.

Leads with PVC insulation and copper core (maximally up to 70°C).

Leads with silicon insulation and copper galvanized core (maximally up to 180°C).

Leads with Teflon insulation and copper galvanized core (maximally up to 205°C).

Leads with Teflon insulation and nickel core (maximally up to 260°C).

Leads with glass-textile insulation and nickel core (maximally up to 350°C).

Leads with mineral insulation and nickel core (maximally up to 450°C).

Option to use epoxy resin filling (temperature in the place of the filling, a maximum of 250°C) – resistant to humidity and contamination by oil, etc.

3) Nickel wire with ceramic insulation (maximally up to 450°C). Applicable for all profiles for flat heating rods.

4) Nickel wire.

Option to use epoxy resin filling (temperature in the place of the filling, a maximum of 250°C) – resistant to humidity and contamination by oil, etc. Applicable for all flat heating rod profiles.

5) Waterproof and resistant to damage by frequent bending of the cable supply.

Three-core cable with rubber insulation and copper core (maximally up to 60°C). Not applicable for flat heating rod profiles 16 mm x 6.5 mm and 22 mm x 6.5 mm.

6) Connection of three-core cable:

Three-core cable with rubber insulation and copper core (maximally up to 60°C).

Three-core cable with PVC insulation and copper core (maximally up to 70°C).

Not applicable for flat heating rod profiles 16 mm x 6.5 mm and 22 mm x 6.5 mm.

7) Three-core cable with silicon insulation and copper galvanized core (maximally up to 180°C). Not applicable for flat heating rod profiles 16 mm x 6.5 mm and 22 mm x 6.5 mm.

8) Leads with glass-textile insulation inserted into the heating rod and nickel core (maximally up to 350°C). Applicable only for flat heating rod profiles 12 mm x 6.5 mm and 12.5 mm x 6.3 mm.

9) Rod with the profile 12 x 6.5 mm, 12.5 x 6.3 mm or 13 x 5.5 mm – Three-core cable with metal braid and glass-textile insulation and nickel core (maximally up to 350°C). Not applicable flat heating rod profiles 9 mm x 4 mm, 16 mm x 6.5 mm and 22 mm x 6.5 mm.